Source auto chlorination dosing machine alum acid floc tank ...

auto chlorination dosing machine alum acid floc tank flocculation dosing system for water treatment plant process, You can get more details about from mobile site on m.alibaba.com

Buy Original automatic dosing system flocculation ... - pharmapackingmachines

Cachedautomatic dosing system flocculation and polymer dosing system filters large gallons of water every day and consumes no energy. It has a simple maintenance, and it's affordable too. Visit pharmapackingmachines.com for the best. automatic dosing system flocculation and polymer dosing system options from trusted sellers and manufacturers. This system is efficient, convenient and eco-friendly.

COAGULATION AND FLOCCULATION - MRWA

Coagulation and Flocculation Process Fundamentals 1 Coagulation and Flocculation . Groundwater and surface water contain both dissolved and suspended particles. Coagulation and flocculation are used to separate the suspended solids portion from the water. Suspended particles vary in source, charge, particle size, shape, and density. Correct ...

Flocculation and polymer dosing | AAQUA NV

CachedAn automatic polymer make-up station consists mostly of three compartments with a dosing screw and a powder storage. In the first compartment (A) the powder is mixed with water. The ratio water/powder can be set-up perfectly. The second compartment (B) is a maturation tank with stirrer (11).

Water Treatment Process: Follow Water Through a Treatment Plant

CachedCoagulationFlocculationSedimentationFiltrationDisinfectionChlorination OperationsConclusionCoagulation is defined as the water treatment process of increasing the tendency of small particles to attach to one another and to attach to surfaces such as the grains of a filter bed. Many surface water supplies contain particles that are too small to settle out of solution on their own. These small particles often carry a small negative chargewhich make the particles repel each other like similar ends of a magnet. Water system operators must use chemicals in order to neutralize these small charges, help the particles attach to one another, and become heavy enough to settle out of solution. A coagulant chemical is injected to neutralize these small negative charges and then the water is rapidly mixed. The rapid mixing disperses the coagulant and also increases the interaction of these small particles. See full list on wateroperatorhq.com Following the coagulant chemical addition and the rapid mix processes, the raw water will continue on to a flocculation basin. The goal of the flocculation treatment process is to increase the size of the flocs in order to increase their ability to settle out. See full list on wateroperatorhq.com The water continues on to the sedimentationbasin, or clarifier, after the flocs have been formed. The goal of this stage of the treatment process is to reduce the amount of solids in the water before the water is filtered in the next treatment step. The large flocs will settle out of suspension via gravity. Clarifiers can remove a very large percentage of the suspended materials in water. In some plants, clarifiers remove as much as 90% of the suspended solids load. Particles that do not settle will be removed by filtration in the next treatment step. See full list on wateroperatorhq.com The final water treatment process in removing particulates is filtration. The sedimentation process will have already removed a large percentage of the suspended solids. Sedimentation is unable to remove many small particles in water though. Filtration will remove these microorganisms and other suspended material that did not settle out previously. See full list on wateroperatorhq.com As discussed previously, the surface water treatment rule requires both the filtration and disinfection of surface water sources. The water must be disinfected now that it has been filtered. See full list on wateroperatorhq.com Chlorination was one of the first drinking water disinfection methods. It is still the most commonly used disinfection method used today. The filtered water is injected with either liquid sodium hypochlorite, gaseous chlorine, or solid calcium hypochlorite. Chlorine is a strong oxidant. It is used to both disinfect and also to remove color, taste and odor compounds, iron and manganese, and other dissolved inorganic contaminants such as arsenic. See full list on wateroperatorhq.com In order to meet the requirements of the Surface Water Treatment Rule, a water system must both remove and inactivate the pathogens in the water. This process begins with coagulation, which destabilizes the particles in the water. Then, during flocculation, the destabilized particles bump into each other and form larger and larger flocs. These large flocs are given adequate time to settle out of solution via gravity during sedimentation. Any remaining particles and pathogens will be removed during the filtration treatment process. Finally, the water is disinfected to inactivate any remaining pathogens prior to entering the water system’s distribution system. By implementing these treatment processes and meeting the Surface Water Treatment Rule, the incidence of water borne disease outbreaks have become a very rare event in industrialized nations and countless lives have been saved. See full list on wateroperatorhq.com

water tank chlorine treatment For Safe Food and Drink ...

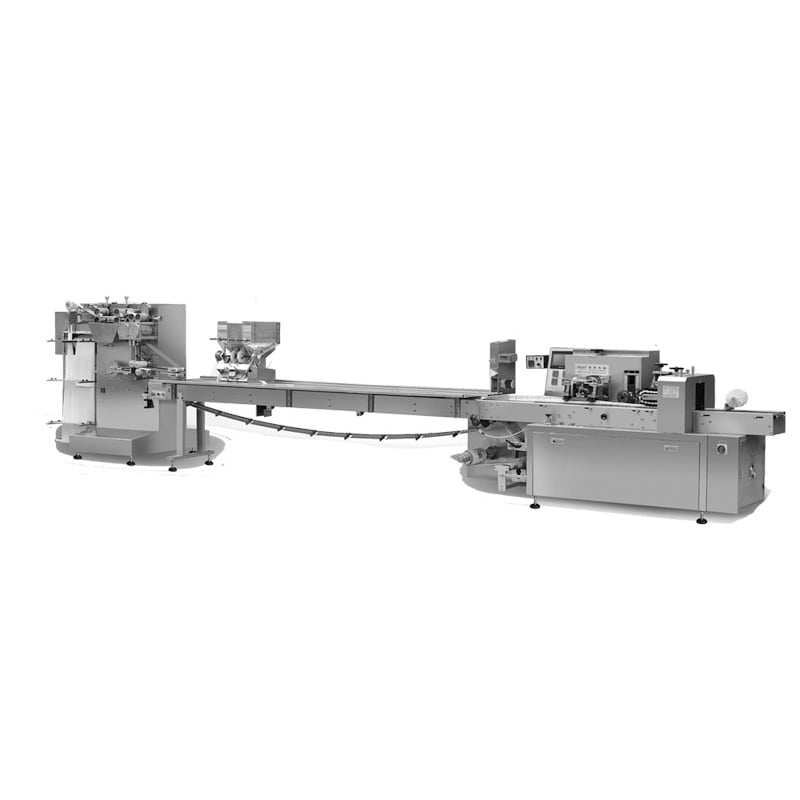

CachedTank Water Treatment Auto Chlorination Dosing Machine Alum Acid Floc Tank Flocculation Dosing System For Water Treatment Plant Process $748.00-$780.00 / Set 1 Set (Min. Order)

Get a quote

Contact Us Now