Flexible packaging is a convenient and sustainable solution for keeping non-invasive pharmaceutical liquids safe and sterile for controlled use at laboratories and medical facilities as well as for inter-hospital transit.

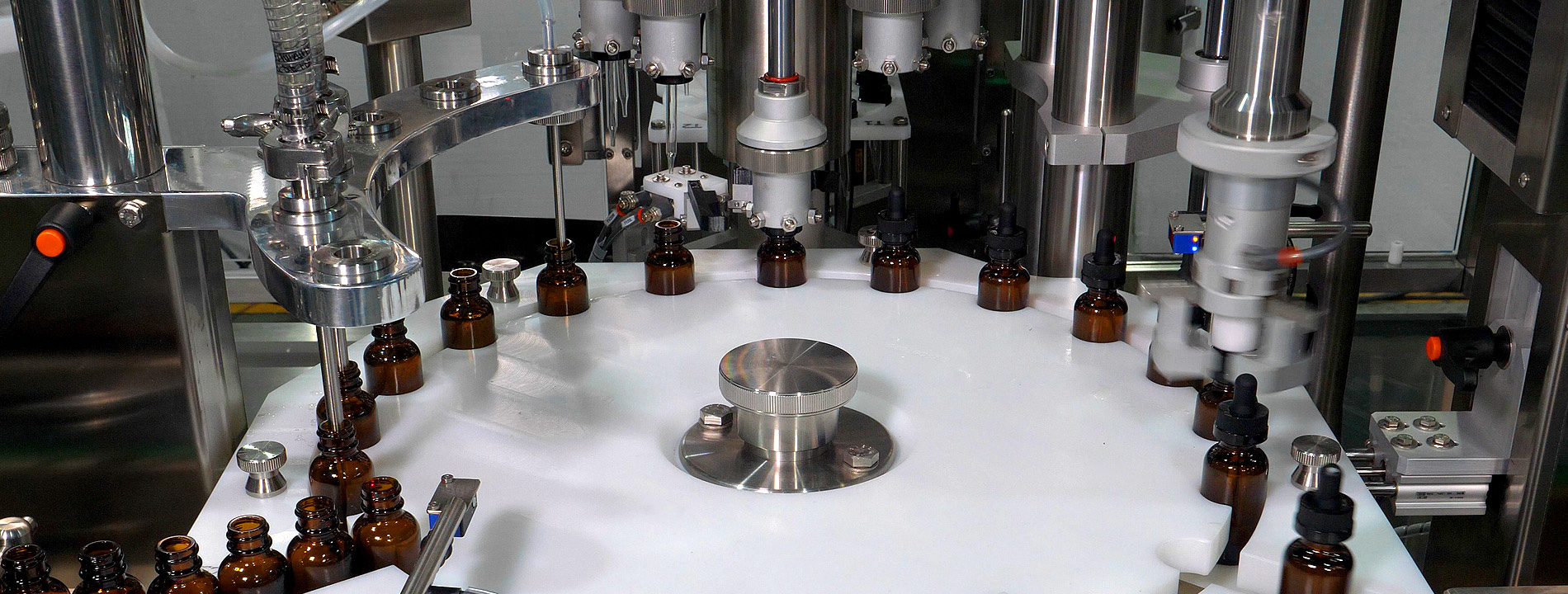

Qualipak’s various types of liquid filling machine ensures sterility for the most sensitive products—whether you are packaging bulk pharmaceuticals in intermediate bulk containers (IBC) for institutional healthcare use, producing oral and eye care products or working with chemicals and solutions for biological testing.

Apart from that,all liquid filling machine provided by Qualipak will also reduce the risk of cross contamination while extending product shelf life and minimizing product waste and environmental impact.

Qualipak’s hard capsule liquid filling and sealing machine can hold liquid or paste into the empty capsules.

It’s a new formulation for pharmacy usage. Our liquid gel cap filling machine combines high technology and exclusive performance, it’s function can reach the international leading level. Besides,the liquid filling and sealing machine also overcome some difficulty filling problems that occur at powder hard capsules. The issues include low bioavailability of insoluble powder, low melting point powder, low-dose material, hygroscopic, and slow-release medicine.

Frequently Asked Questions

Which filling principle will work best with my product?

Liquid filling machine can use a variety of principles to move product from a holding tank to the bottles or containers waiting to be filled. Each principle offers some unique benefit to the packaging process. This question can begin to be answered by looking at the product itself. Thin, free-flowing products are usually filled using an overflow filler or horizontal liquid filling and sealing machine.Thicker, more viscous products will normally require a piston filler or pump filling machine. These are general rules and, of course, exceptions do exist. For example, when a packaging project includes multiple products with a wide range of viscosities, a pump or piston filler may be used with both thick and thin products.

Will the filling machine work with all of my bottles and containers?

The product is not the only consideration when it comes to choosing the correct filling machinery for a given project. The liquid filling machine must also work with the varying sizes of bottles or containers being used for packaging the product. Many filling projects will include more than one bottle size. In fact the bottles may range from a few ounces for travel or sample size products to a gallon or more for bulk containers. Different packaging machines will require different changeover for the bottle sizes. While each machine will be able to handle a range of containers, as that range expands, some liquid fillers will work better than others for quick, efficient changeover and less filler downtime. Changeover time leads to downtime, which in turn can effect total production rates.

What kind of production rates can I expect?

A third consideration when choosing a liquid filling machine is the production rates that can be achieved. The initial assessment of production rates can be achieved through simple math. For example, if an automatic liquid filling machine is manufactured with eight fill heads and can complete 4 fill cycles per minutes, the machine will fill thirty-two bottles per minute, about 1,900 bottle per hour or approximately 15,000 bottles in an eight hour shift. Adjustments, such as adding fill heads or speeding up pumps, can be made to try to increase the production rates. In the end, ensuring that the necessary number of bottles will be filled each day is a fairly simple task. However, most companies that are packaging a product hope for, and expect, growth in the future. The expected growth can make the analysis a little more difficult.

Will company growth make my machine obsolete?

Figuring production rates for the present is fairly simple, but trying to estimate growth and ensuring that a liquid filling machine can handle increased production in the future is a little more difficult. Packagers should make sure that the liquid filling machine chosen has the ability to grow with the company. Many liquid filling machines are upgradeable in more than one way. Some packagers may start with a semi-automatic filler that will allow for the addition of a PLC and indexing system (and therefore automatic production) in the future. Even automatic filling machines can be upgraded to add additional fill heads in the future. Furthermore, the packager can plan ahead by purchasing a machine capable of meeting production demands on a single shift. When growth occurs, additional shifts can be added to meet the demand. In general, a packaging company should simply ensure that the machine they are purchasing is not set on their production floor already meeting it maximum potential for output of product.

Can the liquid filling machine be integrated with my existing equipment?

Not all packagers will automate every aspect of a packaging system at one time. Once the liquid filling machine has been chosen, ensure that the equipment will integrate with existing packaging equipment or with equipment to be purchased in the future. Many automatic liquid filling machines will be manufactured to roll up to any existing power conveyor and begin filling bottles. However, semi-automatic or custom filling equipment may not be as versatile.

Before choosing the most suitable liquid filling machines,you will have to ensure that the machine chosen from the factors considered above has the ability to work well with other packaging equipment to again avoid leaving the company with obsolete machinery should change occur in the future.

Of course, no two filling projects are the same, and each individual project will bring with it additional questions and concerns. Some projects may require filling of a hazardous product or even filling within a hazardous environment. Other projects may have special electrical requirements or the need to do away with electricity completely. Other products may require sanitary filling machines to guard against product contamination.

You will have to work with the machine manufacturer to certain the specific solution and the general questions before the liquid filling machine is manufactured.