Spray Drying Technology Definition, Types, Working Process ...

There are 3 types of commonly used spray dryer machine: pressure spray dryers, airflow spray dryers, and centrifugal spray dryers. Spray drying technology is a good method to obtain ultra-fine dry powder from the material liquid. The material liquid can be a solution, a suspension, and an emulsion, which can be transported by a pump.

Spray drying process : overview, fundamentals of spray drying

Spray drying is a drying method that has developed tremendously in the last 30-50 years. It presents unique advantages to dry materials while preserving them from degradation. It is a very versatile process that can be used at lab scale or within factories producing dozens of tons an hour.

SPRAY DRYING - jnkvv.org

Pressure nozzle is the most commonly used atomizer for spray drying. Nozzles generally produce coarse, free flowing powders than rotary atomizers. Pressure nozzles used in spray drying are called “vortex” nozzles because they contain features that cause the liquid passing through them to rotate. The rotating fluid

All About Spray Drying - Process and Applications in Industry

Spray Drying Processes Spray dryers take a liquid stream and separate the solute as a solid and the solvent into a vapor. A drum or cyclone usually collects the solid. The liquid input stream sprays into a hot vapor stream and vaporizes. As moisture rapidly leaves the droplets, a solid forms.

Spray Drying: An Overview | IntechOpen

Spray drying is a well-known method of particle production which consists on the transformation of a fluid material into dried particles, taking advantage of a gaseous hot drying medium [ 1 ]. Its first observation is dated 1860 and a primitive spray dryer device was patented by Samuel Percy in United States in 1872 [ 1, 2, 3 ].

Spray Dryer Atomization, Spray Drying.

Control of spray dryer wall buildup can be achieved through variations of the spray angle. Two-Fluid Nozzle Atomization Two-Fluid Nozzle A spray is created by contacting two fluids, the feed and a compressed gas. The atomization energy is provided by the compressed gas, usually air. The contact can be internal or external to the nozzle.

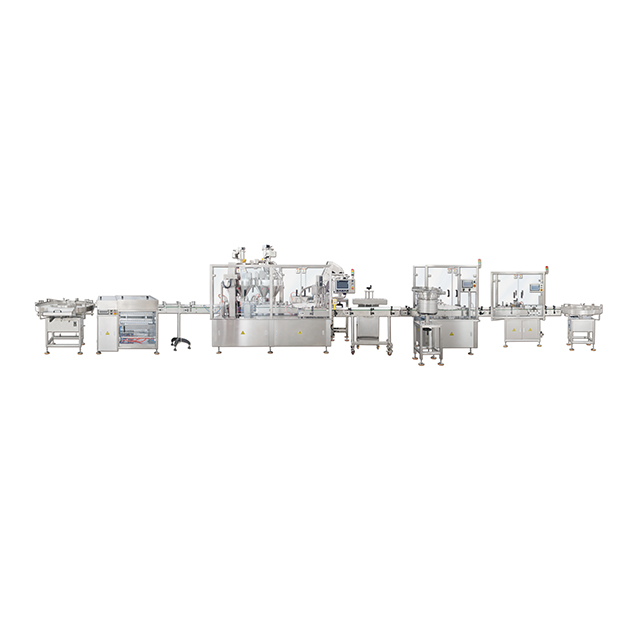

Laboratory Spray Dryer - Yamato Scientific America

Spray Dryers. Yamato Scientific carries highly advanced laboratory spray dryer systems offered in compact, versatile, and large capacity units. Each spray dryer is innovatively engineered to meet essential spray drying needs, our selection of spray dryers cover a vast range of applications for food, pharmaceutical, industrial, and other industries. Through years of valuable experience and outstanding R&D, Yamato continues to provide globally competitive spray drying equipment that delivers ...

Spray Drying Machine, Closed Loop Vacuum Spray Dryer | Hawach

Customized spray drying machine is the dryer of which the speed is over 150L/h. We put vacuum spray dryer and closed loop spray dryer in this category because the three are all high-end products (the two are initially airstream small spray dryer). On this page, the vacuum and closed-loop dryer will be fully elaborated, and if you have over 150L/h speed requirement, contact us for our spray drying machine and we will give you the most competitive price!

Get a quote

Contact Us Now