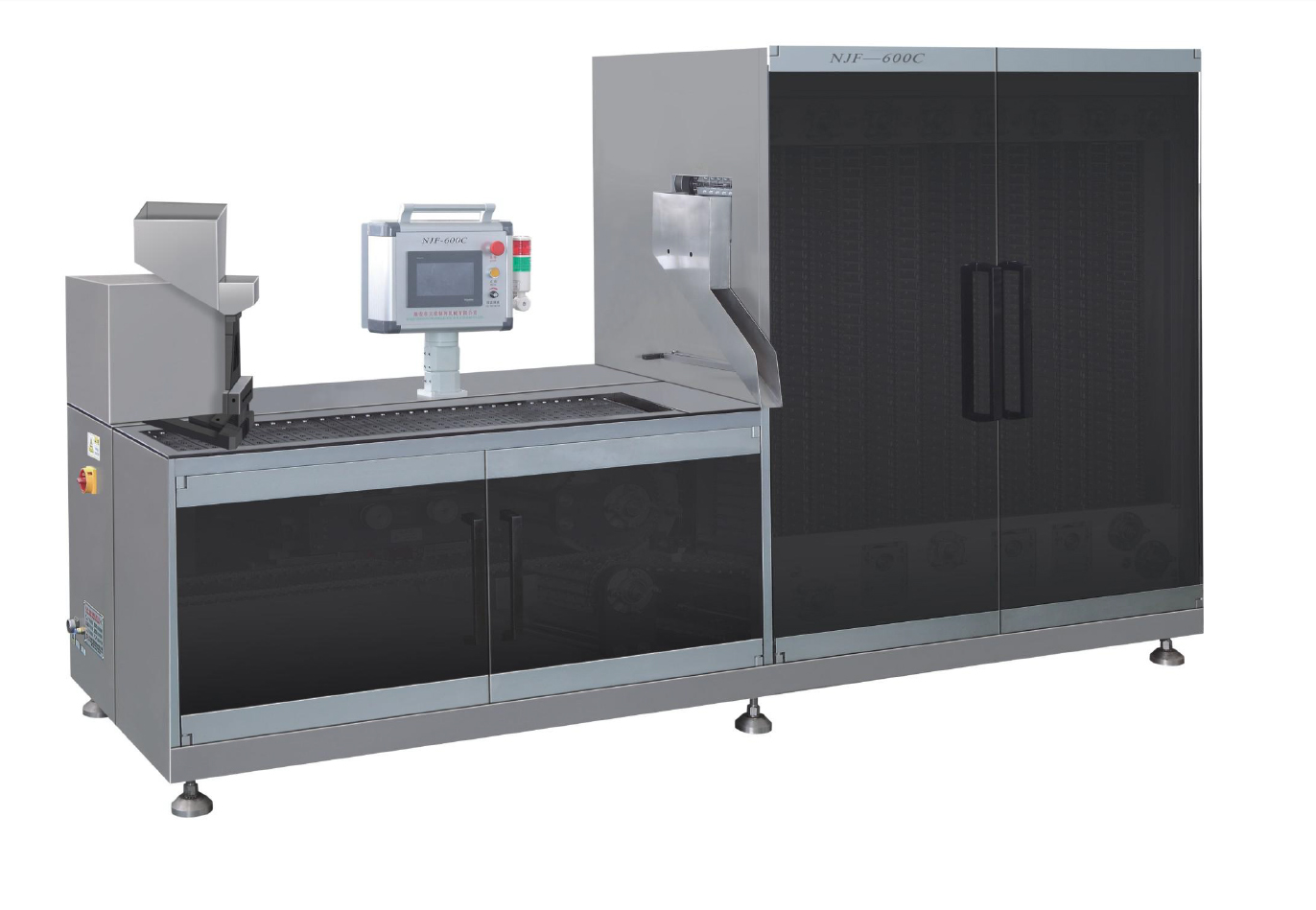

NJF-600C Hard Capsule Sealing Machine

Introduction

|

|

|

1. The equipment adopts man-machine interface control system. 2. The sealing mechanism adopts the servo motor lifting device, which can be used to jog and fine-tune the rubber wheel to achieve the best effect of the sealing layer. 3. The sealing liquid tank is designed as a sealing structure, and is equipped with a heating and heat preservation system to ensure the viscosity of the glue liquid and effectively extend the glue liquid circulation period. 4. The finished dry curing mold adopts hanging type and free rotation structure, which effectively improves the disassembly and unloading cleaning time. |

Specifications

|

Production output |

36,000 / hour |

|

Adapt to capsule |

00-4# gelatin, veggie capsule |

|

Template die hole |

e 6 holes |

|

Sealing material |

Powder, pellets, granules, liquid |

|

Input power supply |

Three-phase 380V/220V 50Hz |

|

Total power |

4KW |

|

Switchboard weight |

1200KG |

|

Dimensions |

2800*900*1900mm (length * width * height) |

|

Environmental requirements |

20 °C or so (room temperature) humid ity 40% -55% |

Machine Detail

|

|

|

Capsule Introduction Device Capsule introduction mechanism, with capsule automatic guiding, optical fiber detection in the capsule plate, capsule high and low position to control the speed synchronization function between the host and the auxiliary machine in real time. |

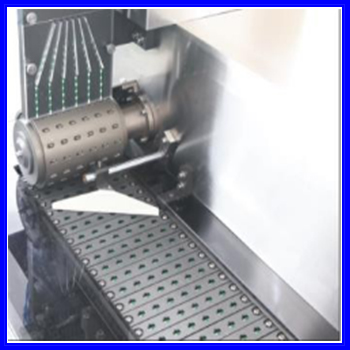

Sealing Gel Device

The lifting and sealing gel table adopts the servo motor control system and the sealed storage glue to effectively prevent the glue from evaporating in the air. There is no heat preservation device inside, the temperature can be adjusted, and the glue can reach the optimal sealing state. The double rubber wheel is used. The secondary gluing technology improves the complete sealing effect at the seal. |

|

|

|

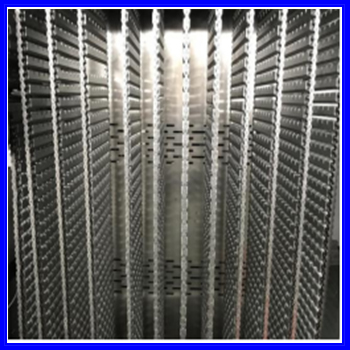

Drying System After the sealing is completed, the capsule is introduced into the drying mold. During the air drying and solidification process, the capsule in the free hanging dry mold hole is always in a face-up state to make a snake-shaped reciprocating motion. Easy to disassemble in terms of mold size and cleaning. |

Outlet Device There are 12 equal-limit ring in the finished product discharge bin. When the dry mold moves to the limit ring, there is a free hanging type to become a fixed-clamp type, so that each unit dry mold rotates 360 degrees, and the finished product is exported to In the discharge bin, 6 blowing pipes are added to prevent the finished product from remaining in the mold. |

Our Service

-

Through years of experience, Qualipak provides several services which cover almost all requirements of clients. These services include production, design, inspection, packaging, shipment, product recommendation, after-sales service, and multiple client solutions.

-

We can supply m§Ñsk raw materials for you if you can’t buy materials from in your local market.

-

We have a good relationship with more than four international shipping companies who have rich experiences in handling different kinds of shipping ways and also the customs declarations and clearances. They all have good shipping services to save you time and costs.

-

We have a professional international technical team. To provide you with after-sales service and guidance.

After-sale Service

We will always be responsible for the machine you purchased. Nearly 10 professional after-sales personnel provide global technical services. In this way, we also provide professional services, such as guide installation services, equipment commissioning and operation services, maintenance services and equipment parts replacement. Ensure the quality of your products, while eliminating your worries.

-

1. The whole machine is guaranteed for 1 years.

-

2. Provide professional machine operation and maintenance guidelines.

-

4. Provide 24-hour online professional technical services .