Good Quality Professional Pure Steam Generator for Pharmaceutical

Cached3. Material: all parts in contact with raw water, pure steam, and pure steam condensed are made of SS316L. 4. Thermal preservation and insulation: the evaporator, preheater, and condenser all use aluminum silicate needle punched blanket, which has good extensibility, light weight, excellent heat insulation and strong stability. 5.

Pure Steam Generators for Pharmaceutical Plant

CachedThe system requires Purified Water and is heated through Plant Steam but can also be heated by Electricity or even Superheated Water. Capacities range: from 20 to 5000 kg/h. Single Effect Distillation Units . Our single effect distillation units can produce both pure steam and WFI, depending on operational requirements and is a perfect solution ...

Purified Water, WFI and Pure Steam Generation

CachedPharmaceutical plant steam production 20 - 5000 kg/h. Purified Water, WFI and Pure Steam Generation. The Honeyman Group has built-up a long-standing reputation as the industry’s leading expert in purified water, WFI and pure steam generation. Our first step in any successful project is being able to clearly define outcomes and goals.

Clean Steam Systems in the Pharmaceutical Industry

Pharmacopeia established definitions for “Pure Steam” and “Pure Steam for Injection” and recommended inclusion of these definitions in the "Water for Pharmaceutical Purposes" section of the USP. At the time of writing this course, that recommendation had not yet been enacted.

Pure Steam and CIP Systems - Water for Injection Systems

CachedPure Steam (PS), often directly called Clean Steam (CS), is the right way to solve the problem of sterilization of the equipment, not only in wfi manufacturing, but virtually in every critical point of any process line (biopharma, food, beverage, cosmetics and so on). Bram-Cor CPSG Pharmaceutical Pure Seam Generators in customized release.

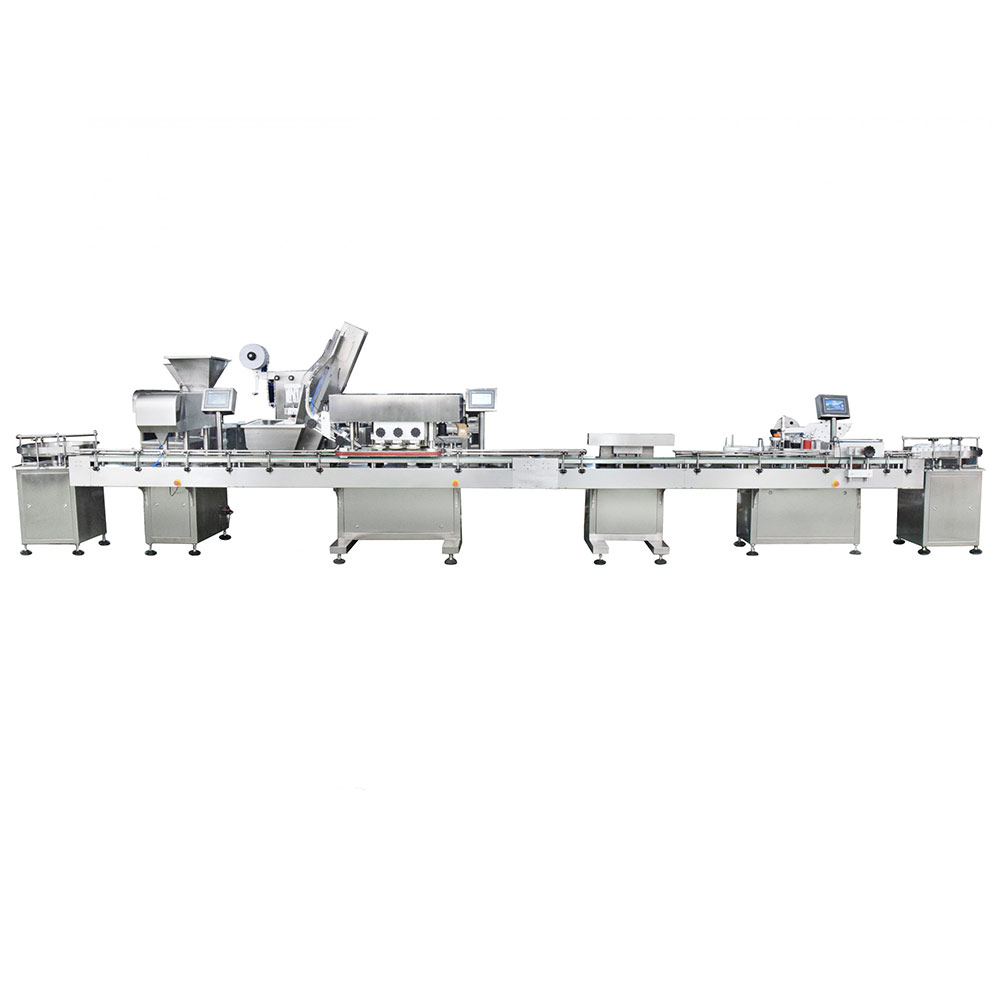

Pure Steam Generator - Komal Water

CachedThe pure steam generation system consists of two columns – Evaporator and Separator. The Evaporator is a shell and tube type of heat exchanger. The driving force i.e. plant steam heats the feed water in the tube side of the evaporator to generate vapour. The generated vapour enters the Separator column. The separator column uses a triple punch separation technique for particle entrainment and separation of impurities such as droplets and pyrogenic material.

Get a quote

Contact Us Now