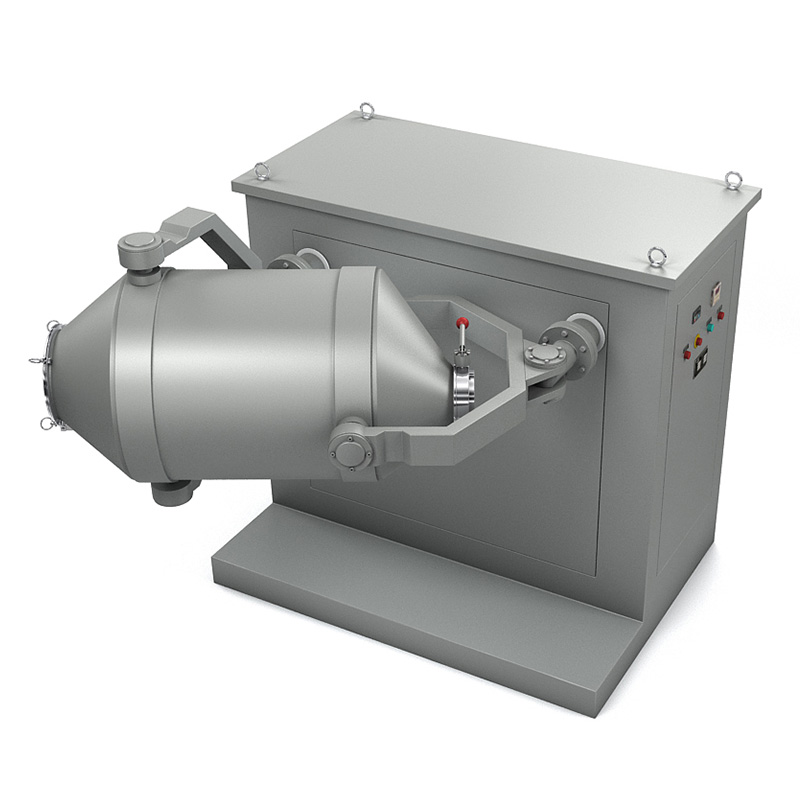

SWH Series 3D Motion Mixer

Description

This machine is applicable for mixing of powdery and granulate material in pharmaceutical, chemical foodstuff, ligh industry, electronic, mining and metallurgy, national defense industry and scientific research institutes.

This machine is composed of base, governor motor shaft, rotary connecting rod and barrel etc., material barrel is driven by the positive shaft to make complex movement including horizontal move, rotation and roiling etc, which makes the material moved to 3 directions along the barrel, therefore, highly uniform mixing of various material is realized. This machine is a kind of full closed high effcient energy saving mixer without germ and dust. When he material is being mixed, no centrifugal force effect and situation of gravity segregation and laminar accumulation are occurred. In addition, it has larger loading capacity, short mixing time and high efficiency.

Feature

- The mixer is provided with three-dimensional movement so that the materials complete the process of mutual mixing from the agglomeration status to dispersion status under the actions of flowing , shearing, translational movement and dispersion, even mixing of materials is ensured and the evenness reaches 99.9%. In ordinary mixers, the materials only make simple dispersion and agglomeration movement in the vessel, which is featured by low efficiency and bad mixing quality.

- With short mixing time and high efficiency, the effective loading rate of the vessel reaches 80%. (The rate of ordinary mixers in only 40%.)

- The machine is low and does not have special requirements for plants, so that investment in basic construction is reduced.

- The mixing barrel and machine body driving part can adopt partition installation to meet GMP requirement.

- For the SYH-2 model mixer, mixing vessels of various shapes can be placed in the mixing barrel for mixing with convenient use.

- Stepless speed adjustment can be realized to facilitate material loading and unloading.

- It is featured by long service life and low noise.

- Vacuum feeding and lifting machine feeding are avaliable.

Data Sheet

| Model | Barrel volume | Max loading volume | Max loading weigh | Mixing time | Spindle speed | Motor power | Overall dimension | Weight |

|---|---|---|---|---|---|---|---|---|

| SWH-10 | 10L | 7L | 7kg | 0-99min | 0-22r/min | 0.18kw | 640*620*55mm | 150kg |

| SWH-25 | 25L | 18L | 18kg | 0-99min | 0-15r/min | 0.55kw | 900*900*75mm | 150kg |

| SWH-50 | 50L | 40L | 40kg | 0-99min | 0-15r/min | 0.75kw | 970*950*120mm | 300kg |

| SWH-100 | 100L | 75L | 75kg | 0-99min | 0-15r/min | 1.5kw | 1200*1600*1500mm | 500kg |

| SWH-200 | 200L | 160L | 160kg | 0-99min | 0-15r/min | 2.2kw | 1400*1800*1600mm | 800kg |

| SWH-400 | 400L | 320L | 320kg | 0-99min | 0-12r/min | 4kw | 1700*2100*1850mm | 1200kg |

| SWH-600 | 600L | 480L | 480kg | 0-99min | 0-11r/min | 5.5kw | 2100*2400*2250mm | 1500kg |

| SWH-800 | 800L | 640L | 640kg | 0-99min | 0-10r/min | 7.5kw | 2200*2500*2300mm | 2000kg |

| SWH-1000 | 1000L | 800L | 800kg | 0-99min | 0-10r/min | 7.5kw | 2280*2600*2500mm | 2500kg |

| SWH-1200 | 1200L | 950L | 950kg | 0-99min | 0-10r/min | 11kw | 2400*2800*2550mm | 2800kg |

| SWH-1500 | 1500L | 1200L | 1200kg | 0-99min | 0-10r/min | 15kw | 2500*3100*2600mm | 3000kg |

| SWH-2000 | 2000L | 1600L | 1600kg | 0-99min | 0-9r/min | 18.5kw | 2800*3600*3200mm | 3800kg |