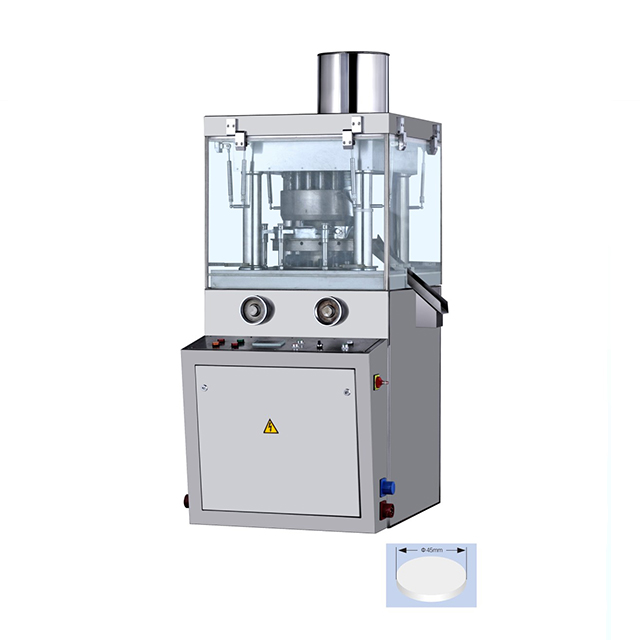

ZP11/ZP18 Rotary Tablet Press Machine

Introduction

|

1. This machine is the single-pressing type equipped with 11 (18) sets of punch dies which are mounted on the workbench and reciprocate upward and downward along the curved guide rail to realize the actions needed for tablet pressing. 2. The operational flow of this machine is: material feeding, filling, tablet pressing, and tablet exporting, continuously. 3. This machine is powered by motors. Through frequency-converting speed adjustment and triangular belt wheel, the work-gear case can be driven, causing the main axle and turret to move clockwise. 4. Rolling friction is adopted in the pressing wheel whose working pressure can be adjusted based on different needs. .Buffer device is also available to prevent the machine from being damaged due to mechanical impact and to elongate the machine¡¯s service life. 5. Periphery of the machine¡¯s working chamber is closed to meet the GMP requirements. Powder-absorbing orifice is installed on the bench surface to purify the working chamber. 6. Thickness of the pressed tablets, working pressure, filling amount, and rotational speed of the workbench are all adjustable. Detailed operations are directed on the operational panel to realize convenient adjustment and easy operation. 7. Material-feeding device is composed of hopper and moon-shaped grate material feeder. The hopper is mounted at top of the machine and can be dismounted. Large-amount single-variety production does not necessitate changing configurations of the machine¡¯s parts. The materials can be directly inputted into the feeder by pipes from the machine¡¯s top, making the operation very convenient. |

Specifications

|

Model |

ZP11 |

ZP18 |

|

Number of Stations |

11 |

18 |

|

Max Main Pressure (KN) |

100 |

|

|

Max Tablet Diameter (mm) |

45 |

30 |

|

Max Filling Depth (mm) |

45 |

30 |

|

Max Tablet Thickness (mm) |

20 |

12 |

|

Max Turret Speed (r/min) |

12 |

20 |

|

Max Production Capacity (pcs/h) |

7920 |

21600 |

|

Motor Power (kw) |

5.5 |

|

|

Overall Size (mm) |

1100¡Á1000¡Á1900 |

|

|

Machine Weight (kg) |

2000 |

|

Our Service

-

Through years of experience, Qualipak provides several services which cover almost all requirements of clients. These services include production, design, inspection, packaging, shipment, product recommendation, after-sales service, and multiple client solutions.

-

We can supply m§Ñsk raw materials for you if you can't buy materials from in your local market.

-

We have a good relationship with more than four international shipping companies who have rich experiences in handling different kinds of shipping ways and also the customs declarations and clearances. They all have good shipping services to save you time and costs.

-

We have a professional international technical team. To provide you with after-sales service and guidance.

After-sale Service

We will always be responsible for the machine you purchased. Nearly 10 professional after-sales personnel provide global technical services. In this way, we also provide professional services, such as guide installation services, equipment commissioning and operation services, maintenance services and equipment parts replacement. Ensure the quality of your products, while eliminating your worries.

-

1. The whole machine is guaranteed for 1 years.

-

2. Provide professional machine operation and maintenance guidelines.

-

4. Provide 24-hour online professional technical services .