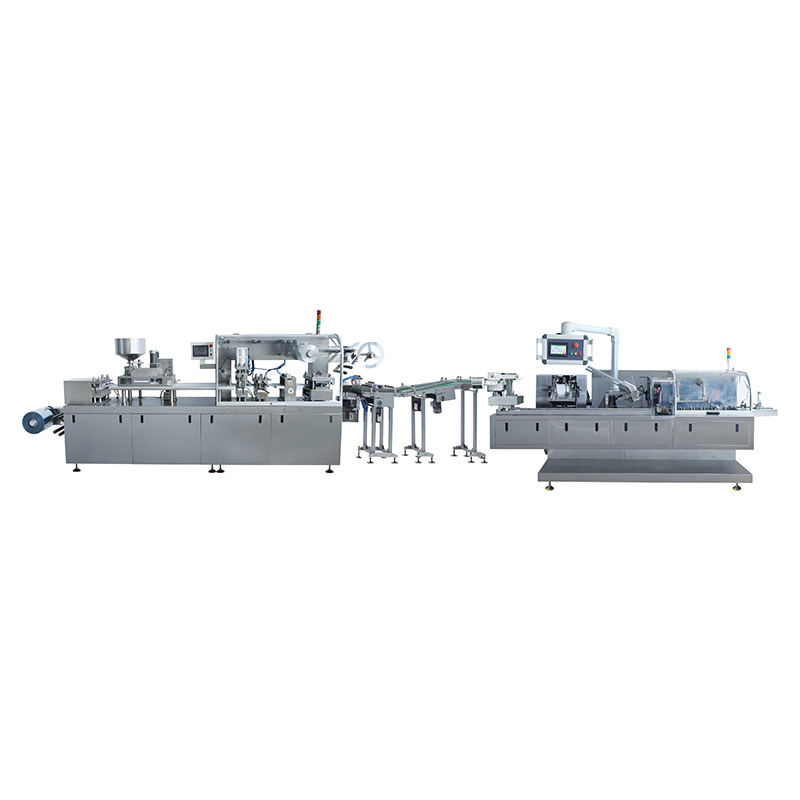

BZX-120B Full-Automatic Medicine Plate Packing Box Production Line Machine

DPP-260H2 imported servo motor traction device improves the running stability performance, and automatically forming, feeding, checking, sealing, batch number (indentation) and punching, testing and rejecting qualified products through the input system into boxing servo feeding system, automatic cartoning machine...

Description

BZX-120B Automatic cartoning production line is DPP-260H2 high speed alu-pvc (Al-Al) blister packing machine and WZH-120 automatic horizontal auto cartoner machine, with the United States Bonner vision inspection systems , real-time monitoring of materials filling and case filling incomplete version of the drug material defects were excluded to ensure that qualified packaged goods, the production line can also increase the packing machine, three-dimensional transparent film packaging machines.

Feature

- The production line uses a separate control system for equipment operation, maintenance, maintenance is very convenient;

- DPP-260H2 imported servo motor traction device improves the running stability performance, and automatically forming, feeding, checking, sealing, batch number (indentation) and punching, testing and rejecting qualified products through the input system into boxing servo feeding system, automatic cartoning machine detection kits, brochures, version after the drug into the box before they were to meet to ensure that products passing rate of 100%;

- Hardware, software, user-friendly design, the whole production line automatic adjustment, saving the waste of resources, improve production efficiency;

- The device transitional soft connection, the production floor space flexible layout, efficient use of space;

- Equipment split packaging, transportation, use of the site is more conducive to handling and installation.

Data Sheet

| Model | BZX-120B | |

| Cutting frequency | Al/plastic 25-60 times/min≥ 100box/min(cartoner) | |

| Al/Al 20-35 times/min ≥ 100box/min(cartoner) | ||

| Production capacity | Al/plastic 6000-140000 (edition/hour) | |

| Al-Al 4800-7200 blister/hour | ||

| Max forming depth | Al/plastic 22mm | |

| Al/Al 18mm (customized forming depth available) | ||

| Carton box | Dimension requirement | (70-180)x(35-85)x(14-50)mm |

| Quality requirement | 250-350g/m2 (base on carton size) | |

| Instruction | Fold range | 1-4 fold |

| Unfolded leaflet specification | (80-250)x (90-170)mm | |

| Quality requirement | 60-70g/m2 | |

| Air consumption | 0.6-0.8Mpa≥ 0.8m3/min | |

| Overall dimensions | 1060(L)X1100(W)X1620(H)mm (line placement) | |

| Weight | About 3400kg | |