High Quality Automatic UBM-40PTG Effervescent Tablets Tube Packing Machine

SED-40PTG Effervescent Tablets Tube Packing Machine

|

Model |

UBM-40PTG |

|

Voltage |

220V |

|

Total power |

1.5kw |

|

Capacity |

20-40 bottles/minute |

|

Supporting facilities |

Purified compressed air whose pressure and consumption are 0.5~0.6MPa and 0.28m3/minute respectively |

|

External dimensions |

2400x1600x1800mm |

|

Weight |

About 480KG |

|

Application |

Tablet diameter: §¶12-23mm Table thickness: 4-8mm Loading quantity:8-30 tablets (Note: One machine only can be used for same diameter tablets and tube) Tube height: 84-144mm adjustable |

|

*Standard machine suitable for |

Tablet diameter 25mm Thickness 5mm Quantity per tube: 20 pcs Tube diameter:29mm Tube height: 144mm |

Composition and Fuction

| 1. Cap vibrating system: Manually put the caps to the vibrator hopper and it will automatically arrange the cap move to the track by the vibrating system for capping.

2. Tablet feeding system: Manually put tablets into the material hopper, and it will automatically send the tablets to the channels for packing preparation. 3. Tube feeding unit: Manually put tube into the tube hopper, the shaking system will automatically send tube to the rack. Tube direction should be checked by manual before put into hopper 4. Cap pushing unit: When tablets push into the tube, cap pushing system will push cap and close the tube automatically, no tablet no capping, no tube no capping. 5. Electronic control section: This machine is controlled by PLC, cylinder and step motor, with automatic multi-function alarm system. |

|

Main electrical components

| No | Name | Brand |

| 1 | PLC | Delta |

| 2 |

Touch screen |

Delta |

| 3 | Main electrical control components |

Schneider |

| 4 |

Cylinde |

AirTac |

| 5 |

Photoelectric, Magnetic switch |

Sick, German |

Note

|

The machine cannot remove all broken grains. It needs to manually clear some broken grains on the track. When the machine detects that there is one tablets less loaded in the tube, it won¡¯t make cap pressing and will make rejection. And when there is no cap in the tube, it also will make rejection automatically. The machine is equipped with a vacuum connection hole, the vacuum cleaner needs to be prepared by the users, and the diameter of the connection hole is 38mm. |

|

Our Service

-

Through years of experience, Qualipak provides several services which cover almost all requirements of clients. These services include production, design, inspection, packaging, shipment, product recommendation, after-sales service, and multiple client solutions.

-

We can supply m§Ñsk raw materials for you if you can’t buy materials from in your local market.

-

We have a good relationship with more than four international shipping companies who have rich experiences in handling different kinds of shipping ways and also the customs declarations and clearances. They all have good shipping services to save you time and costs.

-

We have a professional international technical team. To provide you with after-sales service and guidance.

After-sale Service

We will always be responsible for the machine you purchased. Nearly 10 professional after-sales personnel provide global technical services. In this way, we also provide professional services, such as guide installation services, equipment commissioning and operation services, maintenance services and equipment parts replacement. Ensure the quality of your products, while eliminating your worries.

-

1. The whole machine is guaranteed for 1 years.

-

2. Provide professional machine operation and maintenance guidelines.

-

4. Provide 24-hour online professional technical services .

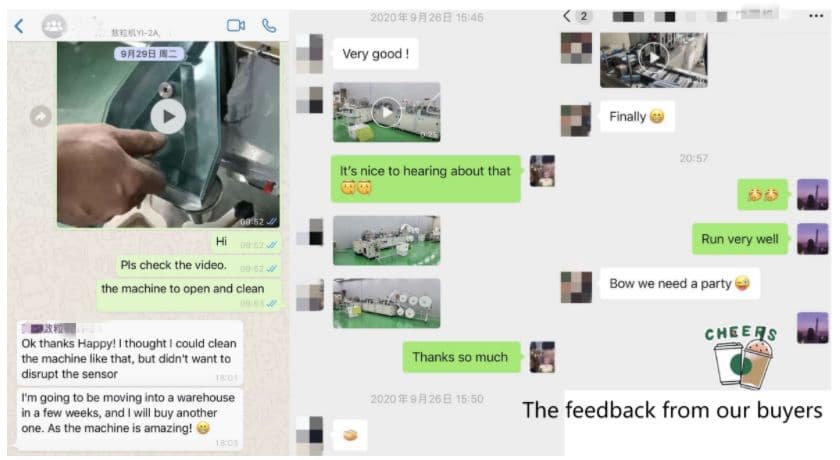

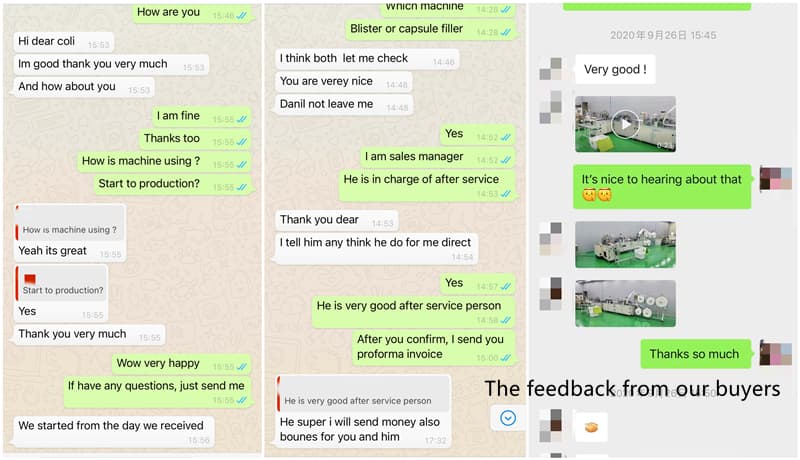

Customer Feedback