High Quality YL-2D Automatic Capsule Counting Machine

As a result, the equipment performance and work efficiency have been greatly improved, the requirement of fast counting drugs such as capsules, tablets and granules are realized, and the stable and reliable state is still maintained du...

Automatic Capsule Counting Machine Parameter

| Model | YL-2D |

| Production capacity | 10-20bottles/min |

| Filling material | 00 ~ 5# capsules, soft capsules,、∅6~18mmound pieces, special-shaped pieces, sugar-coated pieces, 、∅6~12mm pills |

| Loading range | 2 ~ 9999 pills/tablet adjustable |

| Voltage,power | AC110V/220V,50-60HZ ,0.5KW |

| Applicable bottle | 10-500mlround bottle, square bottle |

| The accuracy rate | Above 99.7% |

| Machine dimensions | 1380X670X1550MM |

| Package Dimension | The wooden case 1480X780X1600MM |

| Net weight | 180KG |

| Notes | The production speed difference is related to the variety, size, bottle size and quantity of medicine |

Before Operating:

| (1)Check whether the glass turntable and vibrator are stopped.

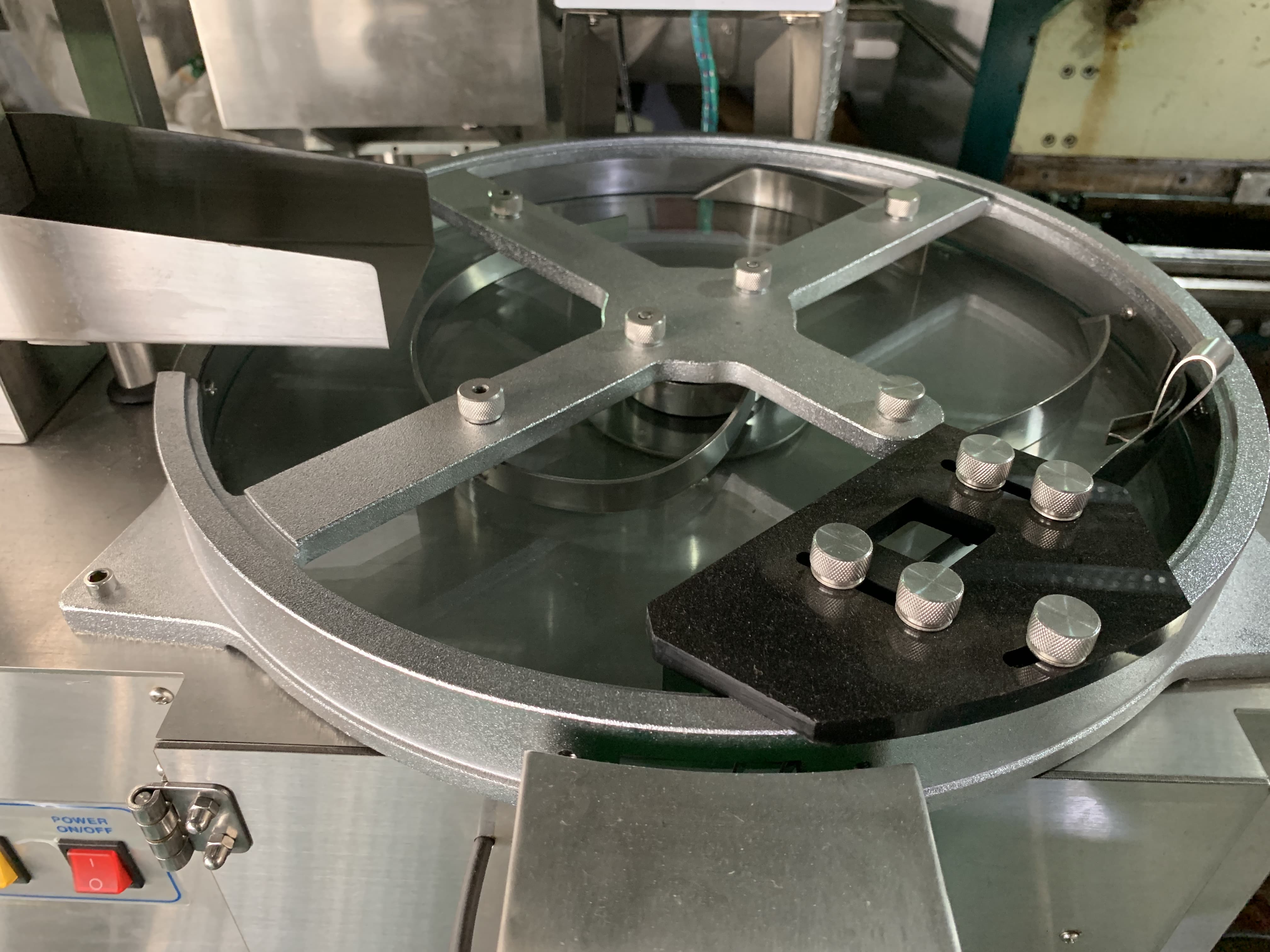

(2)Check the glass turntable and the vibrating discharge tank, no other sundries. (3)Orbiter adjustment method£º 1. The outer track and the inner track should be parallel to each other, the width is slightly larger than the diameter of the tablet or capsule, and the discharge port should be placed in the middle of the electric eye seat. 2. The front end of the outer orbiter should be attached to the circumference so that the capsule will be smooth when sliding. 3. Adjust the orbiter to a height slightly greater than the thickness of the tablet. (4)In accordance with the size of bottle mouth and drug granule, choose the appropriate feeding mouth¡£ (5)Adjust the lifting height, feeding mouth slightly higher than the bottle. (6)Adjust the width of the conveyor belt guardrail, slightly width of the diameter of the bottle, so that it is smooth through;Adjust the limit cylinder to align the bottle mouth with the feeding port. (7)Check whether the 2 sets of power off switches on the conveyor belt (waiting bottle, full bottle) are aligned with the reflector. (8)Connect with the air compressor and connect with the pneumatic pressure regulating valve. (9)Set the quantity, start the turntable and vibrator slowly, check whether the granule slides smoothly and whether the digital display is correct. If all is normal, the number is reset to zero, adjust the speed of the conveyor belt to achieve the best effect of decanting. And then start the operation. |

|

Operating Steps:

| (1)Access to the trachea. | |

|

(2)Turn on the power switch. |

|

| (3)Start granulator: Start the power switch of the body of the granulator. |  |

| (4)Start the conveyor belt: press the ship type switch on the right rear of the conveyor belt and adjust the speed to the corresponding speed (default 90);According to the size of the bottle, adjust the black knob on the lower right of the display to control the decanting time. |  |

| (5) Adjust the height: long press the up/down button, the discharge mouth is aligned with the bottle mouth, the gap is about2- 3MM. |  |

| (6)Wait for bottle and full bottle: when the conveyor belt is short of bottle, the front sensor shows green light, the machine stops working;When the back section of the conveyor belt is full of bottles, the rear sensor shows a green light and the machine stops working. | |

| (7)Set the number of granules per bottle, start the power supply and vibration, adjust the vibration feeding speed, rotary speed, according to different sizes of tablets and capsules, the speed should be adjusted accordingly. | |

Operating:

(1)If there is a lot of powder in the tablet, there are some plastic joints inside the door plate, can be connected to the suction pipe, in order to prevent powder interference with the electric eye affect the accuracy of cleaning electricity, please use a brush or cloth gently wipe.

(2)Adjust the conveyor track speed to match the decanting speed to achieve the best results.

(3)Operation vibration discharge to match the speed of the turntable, disk surface can not accumulate material, so as not to block the track.Pay special attention to the capsule, if the material falls too much, in the orbiter easy to produce overlap or blocking, counting is not accurate.

(4)Pay attention to whether the flashing of the “Sensor Index” on the computer is normal at any time, and spot check from time to time. If the quantity is not accurate, stop and check immediately

Trouble Clearing And Solutions:

(1)Condition: Numbers do not jump, the electric eye indicator has been kept ON

Treatment: 1. Cover the electric eye with powder.

2.The pellet is stuck in front of an infrared emitter

3.Infrared transmitter fault

4.The infrared is not aimed at the electric eye

(2)Condition: Numbers do not jump, the electric eye indicator is always OFF

Treatment: 1. Electric socket is not plugged in well

2.Short-circuit of electrical connection line or drop of welding point

3.Direct lighting or too strong light above the machine

4.The machine is placed outdoors or in a window and exposed to direct sunlight

(3)Condition: Quantity is not allowed (0~3 capsules per bottle)

Treatment: 1. Speed is too fast

2.Pieces doping

3.The outlet position of the orbiter is slightly biased and should be fixed in the middle of the electric eye seat

4.Stator deflector is too high

5.Capsule blanking too much to produce overlap

(4)Condition:The quantity is not accurate (more than ten grains per bottle)

Treatment: 1. Cover the electric eye with powder.

2. Infrared LED failure.

3.The machine is placed in the window and exposed to sunlight.

4.There is too much natural light in the room.

5. Electric eye aging.

6.Poor contact of isolation wire plug, loose solder joint or broken internal copper wire, to poor contact.

(5)Condition: glass turntable does not turn

Treatment: 1. Glass jammed — if you push the glass with your hand, it will not move at all. The glass may be jammed by tablets or rails.

2.The turntable retaining screw is loose.

3.Transmission gear screws are loose and motor reduction gear is worn

4.Check circuits including switch, motor connector, governor, knob, fuse, etc

(6)Condition: The tablet cannot swing from side to side

Treatment: 1.The solenoid valve is burnt out

2.Rod and fork shaker should be lubricated frequently

3.The edge rubs against the metal when installing the switch dial

| (7)Condition: the cylinder gets stuck or more bottles pass by when decanting on the conveyor belt.

Treatment: 1. Fine adjust the speed regulating knob of the cylinder. If the cylinder is rotated clockwise, the expansion speed of the cylinder will slow down; if the cylinder is rotated counterclockwise, it will speed up. |

|

Cleaning And Precautions:

(1)Machine placement place:

1. It should be placed indoors away from direct sunlight and projection lamps, and no radiation equipment should be placed around it.

2.The working table should be level, four feet need to be stable, avoid vibration, the machine is placed in the working table, the appropriate rotation to adjust the feet to make it stable, if there is a move to the machine must be re-adjusted.

3.The room temperature can be normal, to avoid too much moisture, such as non-dust-free room, usually with a cover.

4.Power sockets should be loaded with 220V/110V and above 5A, with a grounding jack.

5.Connect the air compressor

(2)Maintenance:

1.The fuselage must be cleaned after normal use.

2.When the machine is not in use at ordinary times, turn off the switch (turntable and vibrator), the knob to the “0” position, turn off the power switch, such as a long time without the machine, unplug the power cord.

3.After cleaning the machine, reinstall it and make the following tests before use:

A.Infrared automatic filling light: turn ON the main power switch, wait for the SENSOR indicator ON to become OFF, slightly open the door panel, cover the electric eye with the palm (10 beads), the indicator light will immediately become ON, continue to do not let go, about 30-60 seconds will emit BEE BEE sound, hand away the sound will disappear.

B.Test vibrator vibration when there is no noise, the loading hopper outlet should have a slight gap with the vibration groove, otherwise the hopper will produce resonance sound.

C.Test turntable idling, should not emit with the glass squeak friction sound, glass turntable will appear scratches.

D.Test the tie rod from left to right and back by hand, smooth and unimpeded.

B

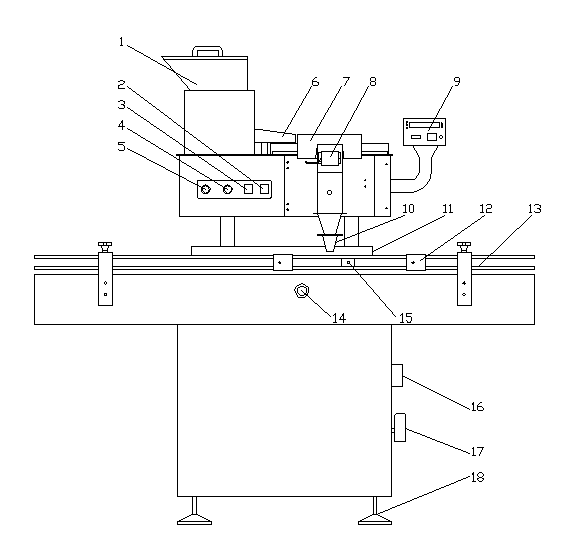

Brief Figure

| 1 Loading hopper | 2 Start switch | 3 Vibration switch |

| 4 Turntable speed regulation | 5 Vibration speed regulation | 6 Vibration bucket |

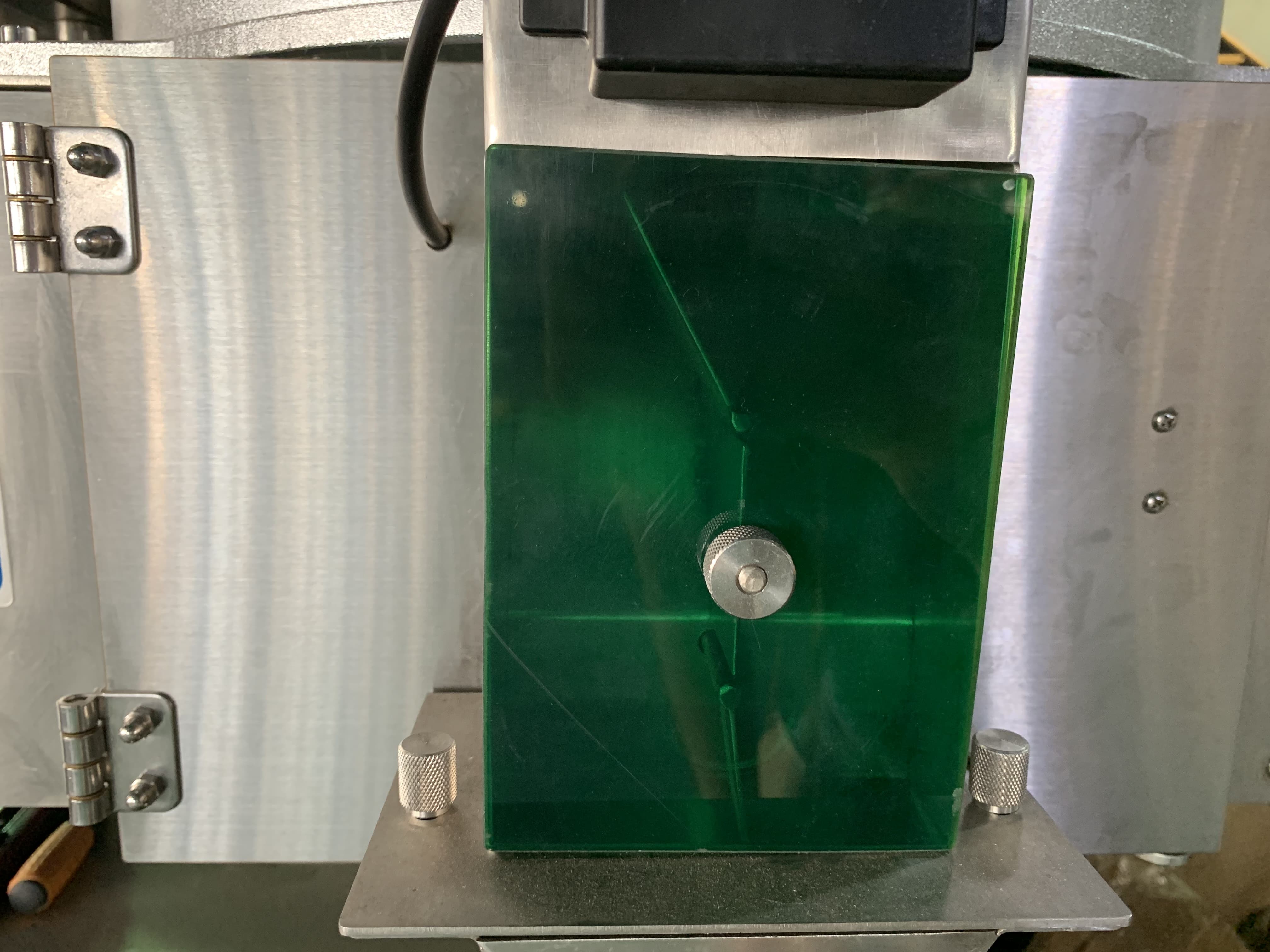

| 7 Lens hood | 8 Photoelectric eye | 9 Electrical box |

| 10 Conical funnel | 11 Lifting table | 12 Bottle sensor |

| 13 Bottle guard | 14 Emergency stop | 15 Limit cylinder |

| 16 Main power switch | 17 Pneumatic pressure regulator | 18 Adjustable base |

Product Details:

|

|

|

|

|

|

|

|

|

|

|

|

Our Service

- Through years of experience, Qualipak provides several services which cover almost all requirements of clients. These services include production, design, inspection, packaging, shipment, product recommendation, after-sales service, and multiple client solutions.

- We can supply m§Ñsk raw materials for you if you can’t buy materials from in your local market.

- We have a good relationship with more than four international shipping companies who have rich experiences in handling different kinds of shipping ways and also the customs declarations and clearances. They all have good shipping services to save you time and costs.

- We have a professional international technical team. To provide you with after-sales service and guidance.

After-sale Service

We will always be responsible for the machine you purchased. Nearly 10 professional after-sales personnel provide global technical services. In this way, we also provide professional services, such as guide installation services, equipment commissioning and operation services, maintenance services and equipment parts replacement. Ensure the quality of your products, while eliminating your worries.

-

1. The whole machine is guaranteed for 1 years.

-

2. Provide professional machine operation and maintenance guidelines.

-

4. Provide 24-hour online professional technical services .

Customer Feedback