Professional YL-8S Capsule Counting Machine

As a result, the equipment performance and work efficiency have been greatly improved, the requirement of fast counting drugs such as capsules, tablets and granules are realized, and the stable and reliable state is still maintained du...

Automatic Capsule Counting Machine Parameter

| Model | YL-8S |

| Production capacity | 1-30bottles/min |

| Filling material | 5#~ 00# capsules, soft capsules,¡¢?7¡«22mm round pieces, special-shaped pieces, sugar-coated pieces, ¡¢?8¡«16mm pills |

| Loading range | 2 ~ 9999 pills/tablet adjustable |

| Voltage,power | 110V/220V,50-60HZ ,0.5KW |

| Applicable bottle | 10-500ml round bottle, square bottle (standard discharge port diameter 22, 28MM) |

| The accuracy rate | Above 99.7% |

| Hopper capacity | 25L (1# capsule can hold 10600 capsules) |

| Bottle height adjustment range | ¡Ü240MM |

| Air supply | 0.6MPA |

| Machine dimensions | 65X109X90MM |

| Package Dimension | 72X115X105MM |

| Net weight | 80KG/110KG |

| Notes | The production speed difference is related to the variety, size, bottle size and quantity of medicine |

Working principle

| This product adopts the principle of photoelectric induction to count, divide and transport the sensed medical particles, and can monitor and set all the operating data in real time. The machine has 8 vibrating “V”-shaped grooves, and the particles automatically transferred into the lower hopper are counted one by one using the vibration effect. The tray is equipped with a bottle-seeing photoelectric eye. If there is a bottle, it will start to work, stop filling according to the set quantity, and repeat the above operation after changing the bottle. If there is no bottle, the vibrating device will stop working. |  |

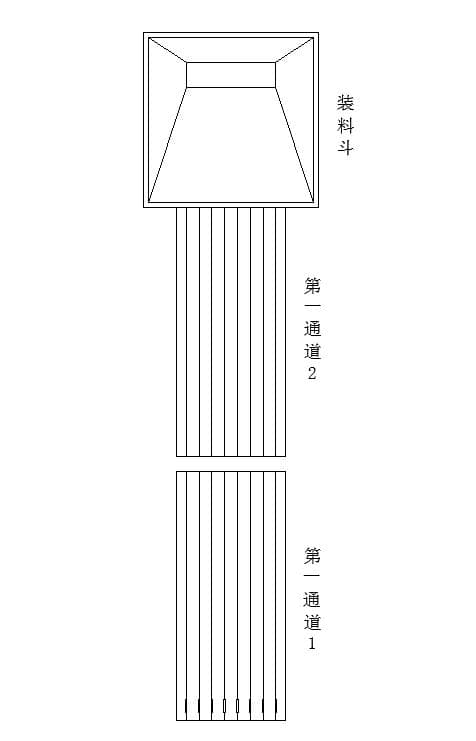

The channel distribution diagram is as follows:

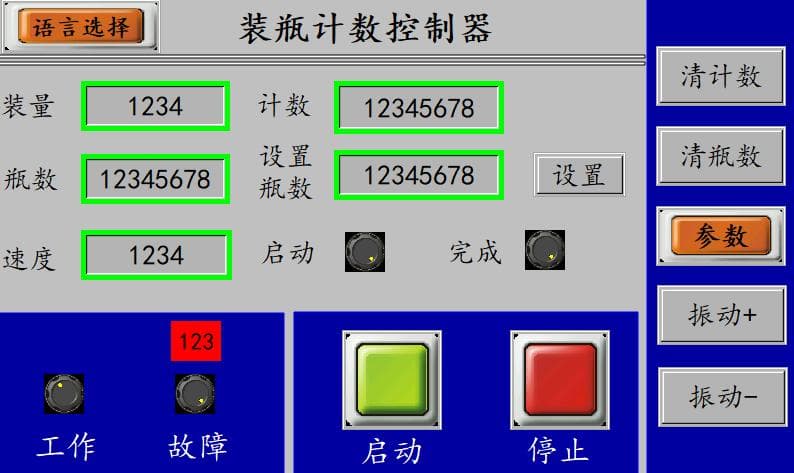

Touch screen operation instructions

| Plug in the power, turn on the power switch:

01. Loading capacity: XXXX XXXX=1-9999(0020) 02. Number of bottles: XXXX XXXX=1-9999(0000) (record the number of bottles in real time) Clearing the number of bottles (clearing individually): first touch the “Stop” button, and then touch the “Clear Bottles” button. 03. Speed: XX XX=1-99(00)bottles/min 04. Count: XXXX XXXX=1-9999 (0000) Counting clear (individual clearing): first touch the “stop” key, and then touch the “clear count” key. 05. Bottle number setting: Set the number of counting bottles, and it will stop working after reaching the value. 06. Start: start running 07. Stop: stop running 08 Vibration+: The speed is fine-tuned to increase the vibration of the first and second stages at the same time. 09 Vibration-: The speed is fine-tuned to reduce the vibration of the first and second stages at the same time. 10. Working light: When the machine is in normal working state, this indicator light is red. 11. Fault light: When the machine is in an abnormal state, this light is on, and the corresponding fault number is displayed. (101-108 are channel faults), if 101 is displayed, it means the first channel is faulty; 80 means communication is faulty; 81 means that when the storage capacity of the medicine warehouse exceeds the setting, it is overdose). |

|

| Parameters:

Touch the “Parameter” key A. Quantity per bottle: XXXX XXXX=1-9999(0020) Adjust the number of bottles B. Transparency threshold: XXX XXX=1-250(210) This value is used to set the maximum sensitivity of each photoelectric eye and can be changed accordingly within a certain range. When this value is exceeded, an alarm will be prompted. C. Transparent series: XX XX=1-20 (1) The transparency of the tablet, this value should be set to a large value, this function conflicts with the maximum filtering length, and the function of filtering debris should be turned off for transparent medicines (set the maximum filtering length). 001). When producing opaque medicines, 1 must be set. D. Fragment shielding: XXX XXX=1-7 (1) When the machine is counting the tablets, when there are broken tablets, shield them so that the counter does not count. The larger the value, the larger the length of the filtered debris, but it may cause a missed count. To use this function, you need to turn off the transparent medicine function (set the transparent medicine sensitivity 1). E. Stop the vibration of the bottle Display 1: It means that when the number of grains reaches 90%, it will slow down and stop the vibration (the debugging value is now 70%). Display 2: Indicates that the frequency division does not vibrate. F. Working mode: display whether the current machine is in normal or mode state. F1. Normal mode: normal number grain selection mode. F2. Simulated drug dispensing: Generally, the mode is selected in the test machine to test whether all aspects of the machine can operate normally. (When counting pellets normally, it must be switched from the simulation drug dispensing mode to the normal working simulation, otherwise it cannot be counted normally). |

|

| Vibration settings

Touch the “Vibration Settings” button to display the following frame: G1.1 level parameters: XXX XXX=1-100(50) Adjust the vibration size of the first level vibrator. Level 2 parameters: XXX XXX=1-100(50) Adjust the vibration size of the second level vibration. G2. Deceleration setting Adjusted as a percentage of normal |

|

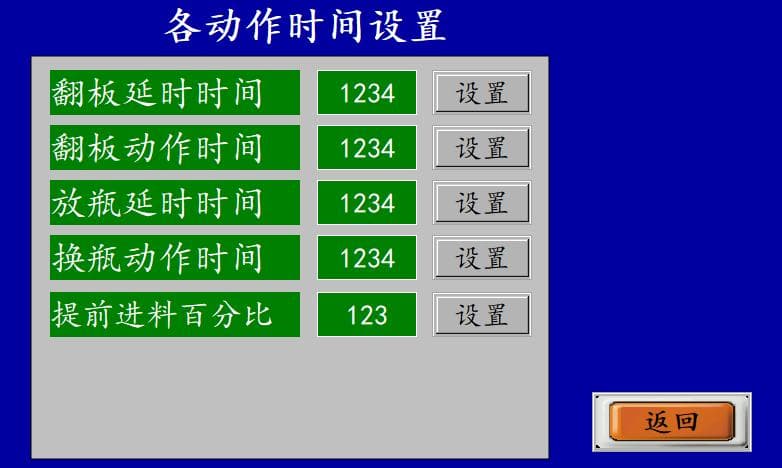

| H. Time setting

Touch the “time setting” key to display the following frame: H1: Flip delay time: XXX XXX=1-100ms (035). This time will affect the accuracy of the bottle separation. If the medicine falls smoothly in the channel and there are too many front bottles, the value is too large; if there are fewer front bottles, the value is too small; in addition, the flipper sprays medicine , or this value may be inappropriate. H2: Turning action time: XXX XXX=1-500ms (350), mainly the time required to perform the turning process, and also used for accurate counting, the setting should not be too small. H3: Delay time of bottle release: XXX XXX=1-500ms (500). If the delay time value of bottle release is too small, there will be medicine in the medicine bucket when the bottle is changed automatically. If it is too large, the overall speed will be slowed down. H4: Bottle changing action time: XXX XXX=0-200ms (120) The above data is the debugging data according to the transparent medicine before leaving the factory. H5: Advance feed percentage: XXX xxx=1-100 The percentage of the material stored in the medicine warehouse, the number is the mode value. |

|

| J: Channel

Look at the value of the photoelectric eye of the secondary channel. This value shows the sensitivity of the photoelectric eye. The smaller the value, the higher the sensitivity. K: Restore factory defaults Touch this key to restore the original factory defaults. L: Save parameters: save parameters after each adjustment. |

|

B

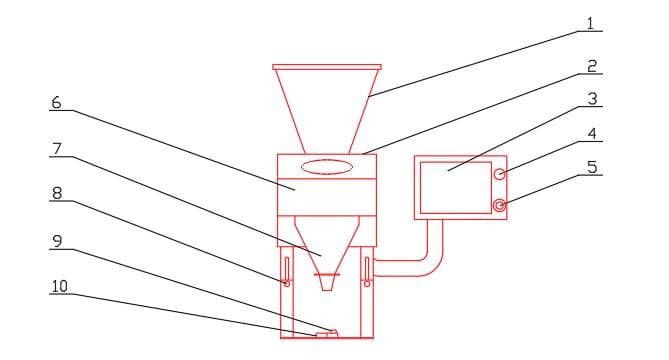

Brief Figure

| 1 Loading hopper | 2 Vibration switch |

| 3 Touch screen | 4 Indicator light |

| 5 Emergency stop | 6 Photoelectric sensor |

| 7 Nozzle | 8 Pallet height adjustment |

| 9 Look at the bottle sensor Bottle guard | 10 Y-type locator |

Product Details:

|

|

|

|

Our Service

- Through years of experience, Qualipak provides several services which cover almost all requirements of clients. These services include production, design, inspection, packaging, shipment, product recommendation, after-sales service, and multiple client solutions.

- We can supply m§Ñsk raw materials for you if you can’t buy materials from in your local market.

- We have a good relationship with more than four international shipping companies who have rich experiences in handling different kinds of shipping ways and also the customs declarations and clearances. They all have good shipping services to save you time and costs.

- We have a professional international technical team. To provide you with after-sales service and guidance.

After-sale Service

We will always be responsible for the machine you purchased. Nearly 10 professional after-sales personnel provide global technical services. In this way, we also provide professional services, such as guide installation services, equipment commissioning and operation services, maintenance services and equipment parts replacement. Ensure the quality of your products, while eliminating your worries.

-

1. The whole machine is guaranteed for 1 years.

-

2. Provide professional machine operation and maintenance guidelines.

-

4. Provide 24-hour online professional technical services .

Customer Feedback