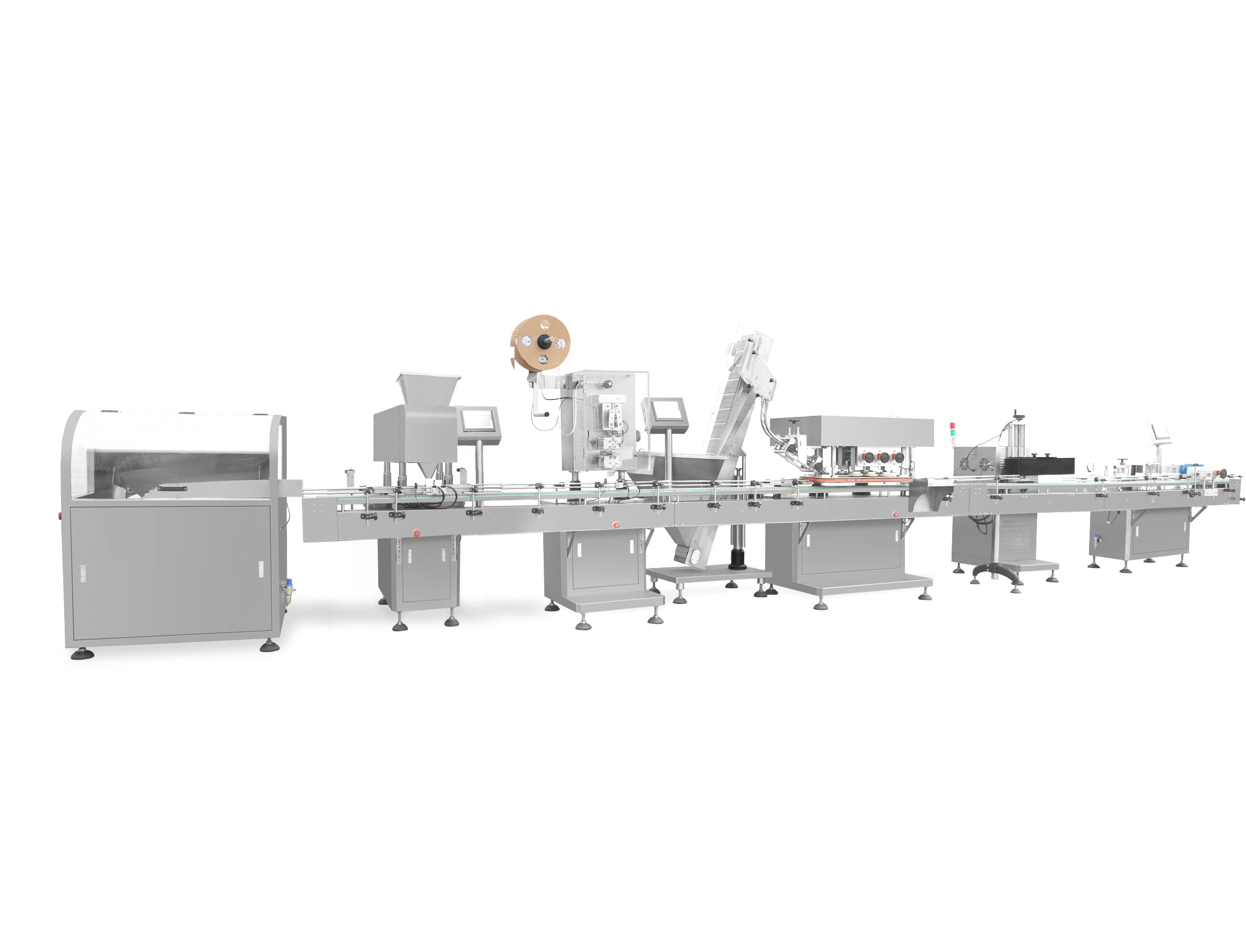

Professional Automatic 16 Channels Capsule And Tablet Counting Line

Introduction

| Item | Basic Machines |

| 1 | UBM-80LP Unscramble bottle machine |

| 2 | UBM-16S Automatic Capsule and Tablet Counting Machine |

| 3 | UBM-CG Linear Bottle Capping Machine with cap elevator |

| 4 | UBM-CG Linear Bottle Capping Machine with cap elevator |

| 5 | UBM-200YT Round Bottle Single Side Labeling Machine with Ribbon Coding Device |

| 6 | UBM-LF Induction Sealing Machine |

| 7 | UBM-900ZP |

Product Details

|

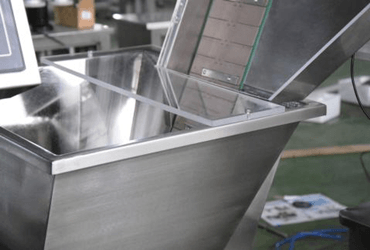

UBM-80LP Automatic Bottle Unscrambler |

|

| The motor runs by the gear then it makes the neatening flower plate work.The bottles in the bottle container rotate from the under part to the upper part of the bottle neatening plate by the semicircle groove of the bottle neatening flower plate.The bottles in the semicircle groove neaten by the bottle turning board of the bottle neatening system.It can turn the bottles which are upside down automatically. | |

| Main Features:

|

|

| Main Technical Parameters: | |

| Bottle type: | plastic round bottle |

| Production capacity: | 50~80 bottles per minute |

| Power supply: | AC220V 50Hz 0.25kw |

| Overall dimension: | 1200×1150×1300mm |

| Weight: | 200kg |

| Configuration: | |

| Name | Manufacturer |

| Electric machinery | Maili Electric |

| Photoelectric sensor | Germany Sick |

| Pneumatic components | Airtec International Group |

| Leakage protection | CHINT China |

| Switch button | Taiwan MeanWell |

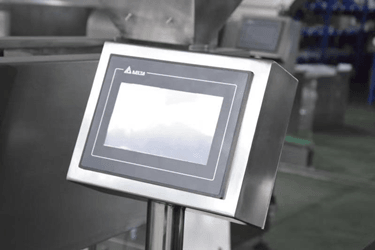

| Human interface | Taiwan Delta |

Product Picture

|

|

|

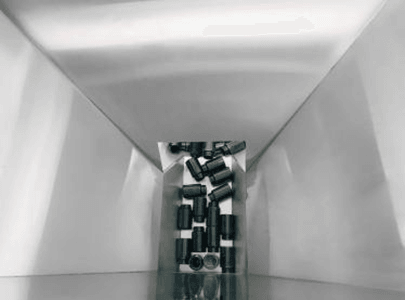

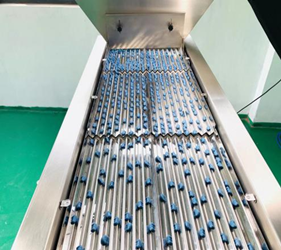

UBM-16S Automatic Electronic Counting Machine |

|

| SED-16 Automatic Electronic counting machine is special for counting tablets, soft gelatin, hard capsule and chewing gums, etc. This machine adopts 16 sets imported counting sensor for counting with 16 Guiding Way and two head. The advantage of the machine is no need change mould when you change the counting object, only adjusting the counting table height by Easy Adjust wheel. The machine comes with Touch screen operation and PLC Control for convenient running. |

| Main Technical Data: | |

| Model Name | UBM-16S |

| Application | 1. Filled capsule(00-5#)

2. Soft Gelatin capsule 3. Ф3-22mm tablet 4. Ф3-20mm pills other solid object under machine range |

| Hopper Volume | 40L |

| Capacity | 20-65 bottles/min |

| Filling Quantity | 2-9999pcs/bottle (adjustable) |

| Compressed air | 0.6Mpa 5L/min |

| Power | 220V/50HZ 0.9KW |

| Machine Weight | 350kg |

| Machine Size L × W × H (mm) | 1360 × 1530 × 1700 |

| Configuration: | |

| Name | Manufacturer |

| Electric machinery | Maili Electric |

| Photoelectric sensor | Germany Sick |

| Counting photoelectric system | SED |

| Pneumatic components | Airtec International Group |

| Leakage protection | CHINT China |

| Switch button | Taiwan MeanWell |

| Human interface | Taiwan Delta |

Product Picture

|

Photoelectric eye will judge whether there is bottle at the feeding mouth (it does not work without bottle) |

The material moves orderly to the medicine chamber through the vibration of the corrugated plate |

Touch screen control |

|

UBM-GS Automatic Desiccant Inserting Machine |

|

| Tablet and capsule are easy to go moist, so it is necessary to put the desiccant into the container to keep medicine away from moisture in order to improve reliability of guarantee period. The machine applies automatic controlling system to take the place of the previous manual operation. The machine can automatically cut the belted desiccant and insert the desiccant bag into the container accurately and speedily. It is available for bottles and pots made of different materials. It features double-lane photoelectric positioning, intelligent feeding length controlling and automatic adjustment of accumulated length error. The electronic controlling system ensures the machine starts when bottles reach working position and stops when bottles are insufficient automatically. The product conforms to the requirements of GMP completely. |

| Main Technical Data: | |

| Bottle Size | 20-300ml |

| Output | 40-100bottles/min |

| Power Supply | 220V 60Hz |

| Power | 0.85Kw |

| Overall Dimensions | 1150*800*1900mm |

| Configuration: | |

| Name | Manufacturer |

| Electric machinery | Maili Electric |

| Photoelectric sensor | Germany Sick |

| Pneumatic components | Airtec International Group |

| Leakage protection | CHINT China |

| Switch button | Taiwan MeanWell |

| Human interface | Taiwan Delta |

Product Picture

|

|

|

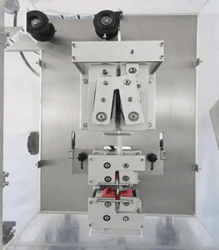

UBM-CG Linear Bottle Capping Machine |

|

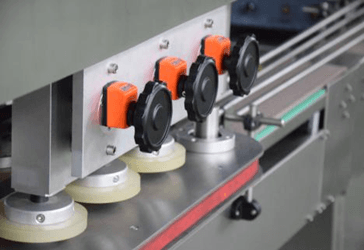

| The machine adopts three groups of friction rollers to screw caps. Screwed caps are not easily damaged by the screwing unit. And if caps are not screwed tightly or tilted, they will be found and rejected automatically. The screw capper is available for various bottles and its changeover is fast and easy. The machine overthrows conventional means of arranging cap by electromagnetic oscillation but arranges caps pneumatically to avoid noise pollution and reduce electric power consumption. It also provides international brand PLC controls, variable frequency controls and photoelectric controls. The machine is incorporated with the device of arranging and lifting cap and a big capacity of cap hopper, so less cap feeding times reduces labor intensity. Generally operators can grasp fluently. The machine conforms to the requirements of GMP completely. | |

| Feature: | |

Fully automatic operation, intelligent joint control with upper and lower processes, good coordination, no need for special personnel to operate, saving labor; |

|

| Main Technical Data: | |

| Size of bottles: | 20-500 ml |

| Output: | 50-150 bottles/min |

| Diameter of caps: | φ20-65 mm |

| Diameter of bottles: | φ20-120 mm |

| Power supply: | 220V 60Hz |

| Power: | 1.5KW |

| Overall dimensions: | 2160*1050*1900 mm |

| Weight | 650KG |

| Configuration£º | |

| Name | Manufacturer |

| Electric machinery | Maili Electric |

| Photoelectric sensor | Germany Sick |

| Pneumatic components | Airtec International Group |

| Leakage protection | CHINT China |

| Switch button | Taiwan MeanWell |

| Human interface | Taiwan Delta |

Product Picture

The material drives the cap to rotate through the cap roller of the bottle clamping belt to tighten the cap |

The cap system will place the cap on the bottle in an orderly way |

|

UBM-LF Induction Sealing Machine |

|

|

Intermediate frequency power supply of the machine makes effective output power great and output current adjustable. It also auto tracks change of current load and makes adjustment in time. If there is no bottle in the specified position, it will stop automatically to save electric power. The machine is available for various bottles. The special sealing induction plate is completely shielded without electromagnetic pollution and its safety is superior to high-frequency power supply. Coding system of the machine adopts built-in water circulation to save water consumption and reduce water pollution; it also has pressurizing system which features good cooling conditions, short sticking time, firm sealing and high stability. Even if the mouth of the bottle is moist with many kinds of liquid, the machine still seals perfectly. If water stop, The machine will sound alarm. Besides, some mechanism protects the machine from being damaged by over current, over voltage and under voltage. And it also has functions of continuous counting and automatic rejection of caps without aluminum foil. The product confirms to the requirements of GMP. |

| Main Technical Data: | |

| Size of bottles: | 20-300 ml |

| Output: | 50-120 bottles/min |

| Diameter of caps: | Smaller than 60mm |

| Height of bottle: | 220mm |

| Power supply: | 220V 60Hz |

| Power: | 2KW |

| Overall dimensions: | 1300*780*1750 mm |

| Configuration: | |||||

| No. | Name | Model | QTY | Specification | Original |

| 1 | Breaker | DZ47-63 C32 | 1 | 30/400V | Delixi |

| 2 | Solid State Relay | CDG1-1DA | 1 | DC12V/40A 480V | Delixi |

| 3 | Bridge rectifier | KBPC5010 | 1 | 50A/1000V | SEP (Taiwan Changhong) |

| 4 | Filter capacitor | 1 | 2200uF/450VDC | Xunshuo | |

| 5 | Transformer | SJW-0452/EI-57 | 1 | 8V -0.8A/16V-0.8A | Shengjiewei |

| 6 | Cooling fan | AC AXIAL FAN | 3 | 0.12A/20W | Elvin |

| 7 | Digital display | HB5153B | 1 | 0~75mV/0~19.99A | Huibang |

| 8 | Power tube | Toshiba | 4 | 50A /500V | Toshiba |

| 9 | Integrated circuit | Motorola | 1 | Motorola (USA) | |

| 10 | Integrated circuit | 4 | AT company, ST company, Fairchild | ||

| 11 | Electrolytic capacitor | Rubycon | 7 | 1uF/16V | Ruby (Taiwan) |

| 12 | Capacitance | MKP-X2 | 1 | 10uF/275V | Create |

| 13 | Polypropylene capacitor | GRAY 335 | 1 | 335J/800V | Shenzhen |

|

UBM-200YT Automatic Round Bottle Labeling Machine |

|

| SED-200YT model vertical type round bottle Round Bottle Labeling machine, in order to achieve rationalization of production target and design. The machine comes with automatic labeling process, simple operation, high speed running, accurate labeling position, beautiful labeling. The machine can be used for pharmaceutical, chemical and foodstuff Industry labeling. | |

| Working Principle:

Put the bottles into the conveyor system (or Auto Bottle Ordering Machine is optional), the conveyor will transport the bottles to labeling station. There is automatic sensor equipped on the machine will sense the passed bottle and feedback to PLC. The PLC gets the signal, then feedback to Step Motor, the step motor supplies the Label to Rotation Pressing Roller which makes the labeling process. |

|

Main Feature:

|

|